The kitchen area is often called the heart of the house – a space for nourishment, collecting, and producing Recollections. When building or renovating this crucial space, aesthetics, operation, and toughness are leading priorities. nonetheless, an more and more important aspect, frequently unseen but deeply felt, could be the affect of products on indoor air high quality. conventional production processes, specially for finishes, can launch damaging chemicals into your house for weeks, months, or perhaps decades. this informative article delves into why deciding on cabinetry with eco-friendly coating procedures, precisely People minimizing risky organic and natural Compound (VOC) emissions, is no more a distinct segment choice but a essential aspect of creating a truly wholesome and present day dwelling ecosystem, specially when purchasing personalized kitchen area cabinets.

Table of contents:

Unmasking VOCs: The Invisible Threat in your house

The eco-friendly Evolution: improvements in Coating Technology

Hallmarks of top-quality Eco-welcoming Finishing procedures

Breathe quick: The Tangible advantages of minimal-VOC Cabinets for Indoor Air

A Sustainable decision: How environmentally friendly Coatings advantage the Earth

The apparent Distinction: regular vs. Eco-welcoming Cabinet Finishes

noticing the healthier Kitchen desire: realistic programs

Unmasking VOCs: The Invisible risk in your house

what precisely are VOCs? Volatile natural and organic Compounds are a big team of substances located in a lot of products we use to develop and maintain our homes. They are termed 'volatile' simply because they effortlessly evaporate into your air at space temperature. While some VOCs are By natural means developing, a lot of person-designed VOCs are concerning elements in paints, varnishes, adhesives, sealants, cleansing materials, and engineered wood products – common elements in conventional kitchen area cabinetry.

widespread sources in cabinetry incorporate solvent-centered paints and lacquers, glues Employed in joinery or substrate manufacturing (like particleboard or MDF), and certain different types of edge banding adhesives. the challenge? several of those VOCs are detrimental to human health and fitness. brief-time period publicity can lead to problems, dizziness, nausea, eye, nose, and throat irritation, and worsening of asthma signs or symptoms. extensive-time period or large-focus exposure is linked to extra severe health issues, including respiratory illnesses, liver or kidney hurt, central anxious program results, and also a heightened hazard of specified cancers. young children, the aged, pregnant Ladies, and folks with pre-present respiratory problems or chemical sensitivities are specifically vulnerable to the adverse outcomes of bad indoor air high quality stemming from VOC off-gassing. being familiar with this threat is step one towards producing much healthier choices for your own home.

The inexperienced Evolution: Advancements in Coating technologies

Thankfully, increasing consciousness of health impacts and stricter environmental rules throughout the world have spurred major innovation in coating technologies. The industry has been steadily shifting far from regular, superior-VOC solvent-primarily based finishes toward Considerably safer, eco-pleasant choices.

Solvent-dependent Coatings: Historically dominant, these use natural and organic solvents to dissolve and have the finish elements. although offering sturdiness, they release sizeable quantities of VOCs for the duration of software and curing.

Waterborne Coatings: These use drinking water as the primary solvent, dramatically cutting down VOC articles. Early variations confronted troubles with sturdiness as compared to solvent-dependent options, but modern-day waterborne acrylics and polyurethanes provide exceptional effectiveness, sturdiness, and aesthetic top quality with appreciably decrease emissions.

UV-Cured Coatings: These finishes contain monomers and oligomers that polymerize (harden) Practically promptly when exposed to ultraviolet (UV) light. this method releases very few, if any, VOCs. UV coatings are known for their Remarkable hardness, scratch resistance, and chemical resistance, producing them ideal for substantial-don surfaces like kitchen area cupboards. The curing course of action is usually really rapid and Strength-economical.

Powder Coatings: utilized like a dry powder and afterwards heated to fuse into a protecting layer, powder coatings incorporate nearly no VOCs. even though more prevalent on steel, improvements are earning them ever more viable for wood-centered substrates.

This change can be pushed by world-wide environmental expectations. laws much like the California Air assets Board (CARB) stage two criteria for formaldehyde emissions in composite wood products and European E1 very low-formaldehyde emission standards have established benchmarks. foremost producers globally now adhere to or exceed these specifications, recognizing that environmental duty and purchaser overall health are paramount. For that reason, high-excellent cabinetry models are more and more adopting lower-VOC or zero-VOC finishing procedures as a typical observe, signifying a commitment to top-quality product high-quality and user wellbeing.

Hallmarks of top-quality Eco-welcoming ending procedures

obtaining genuinely low-VOC and nutritious cabinetry consists of additional than simply switching paint forms; it requires a holistic approach to the producing and finishing approach. Leading companies committed to well being and sustainability generally show a number of key traits:

materials Selection: Prioritizing Qualified minimal-VOC or zero-VOC coatings, which include significant-grade waterborne lacquers or Superior UV-cured finishes. Additionally they frequently use minimal-emission or formaldehyde-totally free substrates (like unique grades of plywood or MDF).

Precision Application: making use of state-of-the-artwork software methods (e.g., automatic spray lines, robotic arms) makes certain a uniform, regular coating thickness. This not only improves the aesthetic appeal and longevity but will also optimizes the curing procedure and minimizes content waste.

extensive Edge Sealing: cupboard edges, In particular Those people of composite wood panels, can be a supply of residual off-gassing from your Main substance or adhesives. significant-good quality edge banding applied with precision using minimal-emission adhesives efficiently seals these edges, stopping VOC leakage and increasing the overall end and longevity.

managed Curing: employing optimized curing procedures, regardless of whether It really is controlled drying environments for waterborne finishes or precisely calibrated UV light exposure for UV coatings, assures the finish hardens entirely and stably, reducing residual emissions.

extensive high quality Manage: Rigorous screening and top quality checks all over the production procedure confirm not only the visual perfection and sturdiness of your finish and also compliance with emission expectations. This ensures the ultimate solution shipped to The shopper is each beautiful and Secure.

These integrated practices result in cabinetry that appreciably minimizes the introduction of damaging chemical substances into the home setting.

Breathe simple: The Tangible great things about small-VOC Cabinets for Indoor Air

The most immediate and major benefit of picking out cabinetry with eco-helpful finishes will be the favourable effect on your private home's indoor air high quality (IAQ). This translates into several tangible Added benefits for homeowners:

more quickly Occupancy & fewer Disruption: in contrast to classic cupboards that might demand times or perhaps weeks of aggressive air flow to dissipate powerful chemical odors (off-gassing), lower-VOC or zero-VOC cabinets launch small emissions. What this means is you may normally make use of your new kitchen presently soon after set up, significantly reducing the disruption and inconvenience linked to renovation.

lessened "New furnishings odor": That pungent chemical odor often connected with new home furniture or cupboards is essentially because of VOCs. Cabinets with eco-welcoming finishes have a much more neutral scent, contributing to a more nice and welcoming instant setting.

A Haven for delicate persons: For households with younger children, pregnant Females, aged members, or people today struggling from allergies, bronchial asthma, or chemical sensitivities, minimizing indoor air pollutants is crucial. Low-VOC cabinetry gets rid of An important opportunity supply of irritants, supporting to produce a safer and more healthy dwelling House for everybody.

extended-expression satisfaction: figuring out that the wonderful new kitchen area is just not slowly releasing destructive chemicals provides a must have relief. It allows you to totally take pleasure in your expenditure with no fundamental health and fitness considerations.

buying low-VOC custom made kitchen area cupboards is basically purchasing the very long-time period overall health and luxury of Your loved ones.

A Sustainable Choice: How eco-friendly Coatings reward the World

the benefits of eco-pleasant coating processes increase past specific houses towards the broader environment. choosing minimal-VOC cabinetry is usually a step to far more sustainable dwelling and supports environmentally conscious producing:

diminished Air air pollution: VOCs add towards the formation of floor-degree ozone (smog), An important air pollutant destructive to human overall health and ecosystems. employing reduced-VOC finishes lowers these emissions with the producing stage and all through the merchandise's life.

decreased Carbon Footprint: Some eco-welcoming processes, like UV curing, are very Electrical power-effective in comparison with the extended drying moments and heat essential for some solvent-centered systems, contributing to decreased Power usage and carbon emissions in the course of output.

Less Hazardous Waste: Waterborne coatings simplify cleanup with water rather then harsh solvents, and UV/powder coatings make fewer waste Over-all when compared with standard spraying approaches, decreasing the stress of harmful squander disposal.

Conference buyer Demand & restrictions: By picking out products and solutions with inexperienced finishes, individuals drive demand from customers for sustainable procedures. This encourages far more makers to undertake cleaner technologies and comply with significantly stringent environmental restrictions around the world. Additionally, it enhances a brand’s track record as liable and ahead-imagining.

The apparent difference: standard vs. Eco-helpful Cabinet Finishes

To fully appreciate the key benefits of fashionable finishing technologies, it helps to match them with standard techniques, In particular more mature solvent-primarily based coatings. the most important distinction is in VOC emissions: standard coatings launch superior amounts of unstable natural compounds all through software and curing, even though modern-day selections like waterborne or UV-cured finishes emit incredibly very low or pretty much zero VOCs.

This right has an effect on the off-gassing interval and odor. standard cupboards often require weeks or even months of ventilation to remove powerful chemical smells. In contrast, low-VOC cupboards have minimal odor, enabling for rapid or much faster use right after installation.

from the health and fitness point of view, substantial VOC articles in conventional finishes can cause allergies, respiratory issues, and pose very long-term challenges. Eco-welcoming finishes tend to be safer, creating them perfect for homes with young children, aged users, or people today delicate to chemical substances.

Environmentally, traditional solvent-based mostly processes add much more to air air pollution and hazardous squander. lower-VOC alternatives lower pollution, and technologies like waterborne coatings simplify cleanup, even though UV curing is Electrical power-successful, decreasing the environmental influence.

Compliance with regulations also may differ. Some standard items could wrestle to satisfy stricter global requirements like CARB stage 2 or European E1. In distinction, eco-helpful finishes from reputable suppliers fulfill or exceed these benchmarks.

Finally, on sturdiness, when traditional solvent-primarily based finishes were extensive seen as essentially the most strong, enhancements in waterborne and UV-cured systems now offer comparable or excellent efficiency in scratch, chemical, and moisture resistance. This gets rid of the trade-off involving sturdiness and health and fitness, making lower-VOC finishes the crystal clear choice for All those prioritizing excellent and security. For buyers planning to purchase kitchen area cupboards from China, numerous best producers now use these State-of-the-art, more healthy ending technologies, giving globally competitive, Secure products and solutions.

Realizing the healthful Kitchen Dream: useful apps

The demand from customers for healthier household environments is reflected in acquiring selections throughout various segments. very low-VOC cabinetry is more and more specified for:

High-finish Residential Projects: Homeowners investing drastically in tailor made kitchen area cupboards hope the best in the two aesthetics and well being specifications.

Health-acutely aware Developments: Builders and developers specializing in wellness communities or LEED-Accredited properties prioritize materials with lower environmental and health and fitness impacts.

family members with Children: mothers and fathers are acutely informed of creating Secure environments for their youngsters, earning lower-VOC finishes a non-negotiable element for nurseries, playrooms, and relatives kitchens.

Renovations for delicate men and women: Homeowners handling allergies or respiratory ailments actively find out resources that won't exacerbate their health problems.

Feedback consistently highlights the difference: designers report smoother venture handovers without the need of client complaints about odors, builders respect Conference wellbeing benchmarks quickly, and homeowners Convey higher gratification with the speedy usability and cozy air high-quality in their new kitchens.

Choosing kitchen cabinets consists of a large number of choices, from design and style and layout to resources and hardware. However, the invisible facet of ending technological know-how and its influence on indoor air good quality need to be a primary consideration. Eco-pleasant coating processes that lessen or remove VOC emissions symbolize a big improvement, offering a immediate pathway to your more healthy house setting without the need of compromising on toughness or natural beauty. It transforms the kitchen from only a purposeful House into a sanctuary that truly supports the wellbeing of its inhabitants.This dedication to wellness and sustainability is a hallmark of forward-wondering producers. Companies specializing in premium tailor made kitchen cupboards, for instance UnionlandsCabinetry, acknowledge this responsibility. By integrating Highly developed minimal-VOC finishing procedures into their manufacturing, they supply items that are not read more simply visually spectacular and developed to past but additionally add positively to generating much healthier, safer, plus much more pleasing dwelling spaces for families around the world. This emphasis represents far more than simply superior manufacturing; it is a elementary determination to the tip-consumer's overall health and satisfaction.

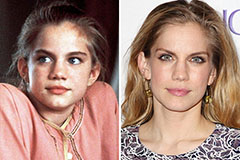

Anna Chlumsky Then & Now!

Anna Chlumsky Then & Now! Mason Gamble Then & Now!

Mason Gamble Then & Now! Kelly Le Brock Then & Now!

Kelly Le Brock Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!